A squeak or chirp from under the hood has a way of grabbing your attention fast. It might only happen for a few seconds after startup, or it might show up when you turn on the AC. Either way, once you hear it, you start listening for it on every drive.

Serpentine belt noise usually is not random. It tends to follow a predictable aging process, and it often involves more than just the belt itself. The belt, pulleys, and tensioner all work together, so when one starts wearing, the whole system can get louder.

What The Serpentine Belt System Does Every Time You Drive

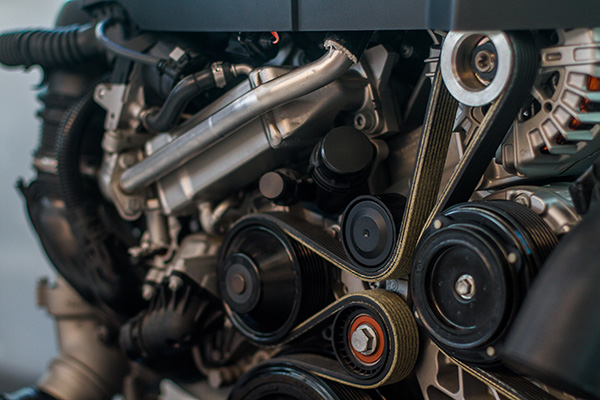

The serpentine belt is a single belt that drives multiple accessories, such as the alternator, power steering pump on some vehicles, and the AC compressor. It loops around several pulleys, and the tensioner keeps the belt at the correct tightness so it grips without slipping.

Because the belt is constantly moving and bending, it wears with time and heat cycles. The pulleys and tensioner also wear because they spin every time the engine runs. When noise starts, it is usually a sign that the grip, alignment, or bearing condition is no longer ideal.

How Belt Age And Heat Create Noise

Belts harden as they age. Rubber loses flexibility, the ribs can glaze, and tiny cracks can form. A hardened belt does not conform to the pulley grooves as well, so it can slip slightly, especially during cold starts or when accessories load up.

Heat makes this worse. Under-hood temperatures can be high, and belts live close to hot components. Over time, heat can dry the rubber and reduce its ability to maintain grip. That is why an older belt may squeal more during startup or during heavy electrical load when the alternator is working harder.

You may also notice noise changes with humidity. Moist air can change how the belt grips, which is why some drivers notice belt noises more on damp mornings.

Pulley Bearings: A Common Source Of Chirping And Grinding

Not all belt noises are belt noises. Many noises come from pulley bearings. Idler pulleys and tensioner pulleys spin constantly, and their bearings can wear out. When they wear, they can chirp, squeal, or even create a rough grinding sound.

A pulley bearing noise often has a sharper, more mechanical tone than a belt slip squeal. It may also persist longer than a brief startup squeak. If you hear a repetitive chirp that rises with engine speed, a bearing is a strong suspect.

Catching a bearing early matters. A failed pulley bearing can seize and shred the belt, which can leave you without charging and without other belt-driven functions.

The Tensioner’s Role And Why It Gets Noisy

The tensioner is a spring-loaded component designed to keep consistent belt tension as the belt stretches and as the engine load changes. Over time, the tensioner spring can weaken, or the tensioner pivot can wear. When that happens, belt tension can fluctuate.

A weak or worn tensioner can allow belt slip, especially during startup or when accessories engage. It can also create noise if the tensioner pulley bearing is worn. Another clue is belt flutter. If the belt looks like it is vibrating or bouncing more than usual, tension control may be weak.

In our shop, we often see tensioners that look fine at a glance but have lost the stiffness needed to maintain consistent belt grip.

Alignment And Contamination Issues That Create Noise

Belt systems rely on alignment. If a pulley is slightly misaligned, the belt can track incorrectly and make a squeal or chirp. Misalignment can come from a worn pulley, a failing accessory bearing, or improper installation after a repair.

Contamination is another overlooked cause. Oil or coolant on the belt reduces grip and can create noise. Even a small leak can coat the belt and cause repeated chirping. If you notice belt noise along with an oily smell or visible residue under the hood, checking for leaks is part of the fix.

A Practical Way To Tell What You Are Hearing

- Noise only at startup that fades quickly can point to belt age or momentary slip.

- Noise that increases with electrical load, like headlights or rear defrost, can point to belt slip under alternator load.

- A chirp that tracks engine speed closely can point to a pulley bearing.

- A rough grinding sound can suggest a bearing that is near failure.

- Belt noise that returns quickly after replacing a belt can point to a worn tensioner or pulley that was missed.

At B & L Automotive, we’ve seen plenty of cases where a new belt was installed, but the real cause was a weak tensioner or a noisy idler pulley. Fixing the whole system right is what keeps the noise from coming back. Fixing the issue right the first time, makes our customers come back to us again and again.

Get Serpentine Belt Service in Newport News, VA, with B & L Automotive

We can inspect the serpentine belt, pulleys, and tensioner, identify what’s causing the noise, and replace the components that are actually worn. We’ll also check for alignment and leaks that can shorten belt life, so the repair holds up over time.

Call B & L Automotive in Newport News, VA, to schedule service and keep your belt drive system quiet and reliable.